Product Features and Specifications

- General Product Information

-

AIR DRIVE CONTROLS INCLUDED

AIR DRIVE CONTROLS INCLUDED

HIGH-PRESSURE GAUGE AND RETURN VALVE

5 OR 10 GALLON STAINLESS STEEL RESERVOIR

AVAILABLE WITH 10-5 AND 10-6 SERIES PUMPS

COMPONENTS INSTALLED ON TOP OF THE RESERVOIR

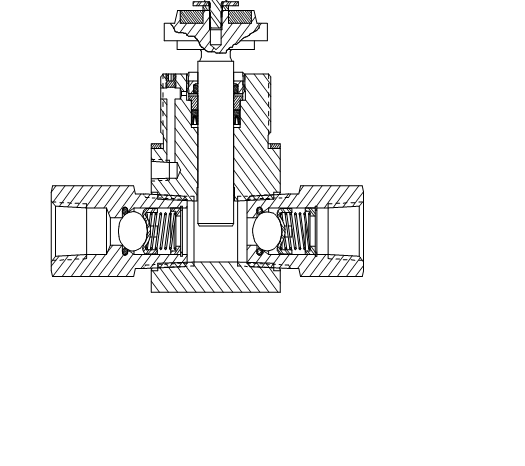

The 60 Series allows for the largest available reservoir capacity, yet provides a footprint (base dimensions) only slightly larger than the 30 Series.

The unit is available with either a 5 or 10 gallon stainless steel reservoir equipped with level gauge, breather/fill cap and bottom drain.

Only two connections are required; air and work port.

Two pressure ports, one equipped with a manual valve, provide ease of control during operation.

Air exhaust muffler provides for quiet operation.

3 1/2" dial liquid filled gauge is included on units up to 280:1 on 10-5 units and 240:1 on 10-6 units; optional on the higher pressure units.

-

- Applications

-

Staking

Piercing

Pressing

Blanking

Clamping

Flow testing

Metal forming

Static and burst testing

Hydraulic press operation

-

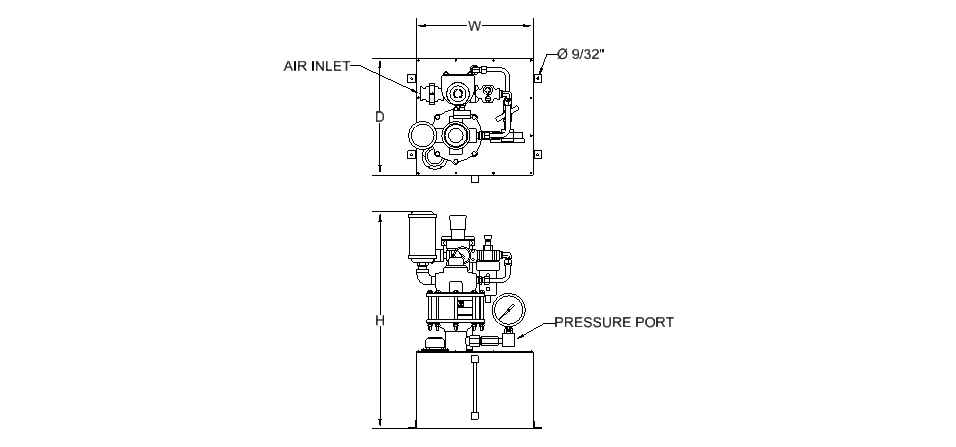

- Dimensions

-

Model No.

Standard10 Series Hyd

Section CodePump Ratio Gauge

PressureOverall Dimensions (in) Ports NPT/High Press. W D H Air Inlet Pressure 5 Gallon 10 Gallon 60-5 Series 005, 007 10:1, 12:1 0-2,000 14 14 23.63 29.5 1/2" 1/2" 010 20:1 0-3,000 015 25:1 0-5,000 3/8" 018, 020 30:1, 35:1 0-6,000 030, 040 55:1, 70:1 0-10,000 045 85:1 0-15,000 060 105:1 0-15,000 1/4" 080 140:1 0-20,000 080-HF4 140:1 0-20,000 9/16"-18 * 100 195:1 0-30,000 1/4" 100-HF4 195:1 0-30,000 9/16"-18 * 160 280:1 0-30,000 1/4" 160-HF4 280:1 0-30,000 9/16"-18 * 250 440:1 No Gauge ** 1/4" 250-HF4 440:1 No Gauge ** 9/16"-18 * 60-6 Series 010 20:1 0-3,000 14 14 26.88 32.75 1/2" 015, 020 25:1, 35:1 0-6,000 030 55:1 0-10,000 3/8" 050 95:1 0-15,000 080 145:1 0-20,000 100 180:1 0-30,000 1/4" 151 240:1 0-30,000 151-HF4 240:1 0-30,000 9/16"-18 * 201 330:1 No Gauge ** 1/4" 201-HF4 330:1 No Gauge ** 9/16-18 * 301-HF4 460:1 No Gauge ** * Coned and threaded high pressure connection for 1/4" O.D. tubing.

** Consult factory if gauge is desired.

-

- Ordering

-

TABLE 1 Power Unit Designation (4) 6 60 Series TABLE 2 Reservoir Option 0 No Reservoir 6 Five Gallon 7 Ten Gallon TABLE 3 Pump Series Designation 4 10-4 Series 5 10-5 Series 6 10-6 Series TABLE 4 Seal Compound - Air Motor 0 Buna-N nitrile (standard) V Viton TABLE 5 Seal Compound - Hydraulic Section 0 Buna-N nitrile (standard) E EPR - ethylene propylene V Fluorocarbon * Consult factory for special compounds TABLE 6 Modifications 0 Standard pump A "A" modification B Bottom inlet (1) D Bottom inlet - heavy duty E Bottom inlet - "A" modification (1) G Isolator - heavy duty (1,3) H Heavy duty (1) J Bottom inlet - "K" modification (1) K "K" modification (1) M Bottom inlet - "A" and "K" modification (1) N Isolator - "A" modification (1) P Isolator - "K" modification (1) Q Isolator - "A" and "K" modification (1) R Isolator (1) S Heavy duty - "K" modification (1,3) U Heavy duty - bottom inlet - "K" mod. (1,3) V Heavy duty - isolator - "K" modification (1,3) TABLE 7 Material of Construction - Hydraulic Section W Aluminum bronze & stainless steel S All stainless steel C Cad plate carbon steel, stainless steel (2) TABLE 8 Pressure ratio model designation Refer to pressure ratio charts for proper selection

Use suffix "L" if lube style pump is included, leave blank for non-lube "Dry Seal" typeTABLE 9 Port option Blank Standard SAE Straight thread as indicated on chart HF4 9/16-18 x 1/4" OD tube 60K psi Notes: (1) Do not fill gap on a two digit description (2) 25 piece minimum order (3) "A" modification included with all "H" modifications (4) Do not fill gap on a two digit description (5) If digit from Table 1 is 6, this letter must be B,D,E,J,M, or U

-

- Modifications

-

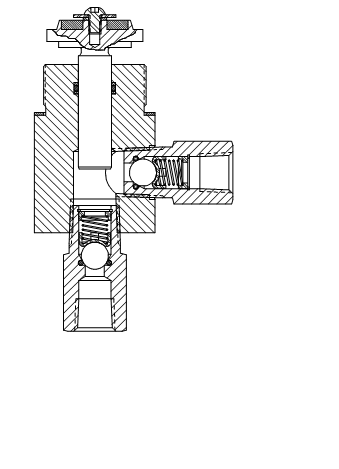

A Models:These models utilize dual seals in the hydraulic assembly with a bleed-off between the seals to atmosphere, thus providing a visual indication of hydraulic seal leakage. Used where contamination of the air motor from the hydraulic fluid being pumped is objectionable.

B Models: The "B" models have a bottom inlet connection for convenient tank top installation or alternate mounting configuration.

H Models: The "H" Models utilize special packing in the hydraulic assembly for maximum performance where hydraulic fluid media is contaminated with foreign matter, thus providing for a much greater life expectancy from the hydraulic seals than with standard o-ring seals. The "A" modification is included on all "H" models and the check valves have PTFE o-rings.

K Models: This models utilize a special air piston in the air motor assembly which decreases the stroke of the pump, thus minimizing the internal forces and increasing air motor life. Used in applications exhibiting rapid pressure losses, such as burst testing. R Models: The "R" Models are furnished with an isolator attachment which prevents the hydraulic piston retracting into the air motor during operation, thus providing for 100% non-contamination of the hydraulic assembly from the air motor. The isolator also acts as a heat barrier.

-